Skinned Sponge Rubber

Often we have materials that we deal with on a daily basis that come with a surface finish. The materials that we most often encounter with notable surface finishes are sponges/foams. These sponge-like materials typically come with a “skin” on both sides. There are a number of different finishes available- fabric finish, smooth finish, extra fabric finish, and skived finish(this is done with a skiving machine). We see many types of polymers as NEDC:

- Viton® Sponge

- Silicone Sponge*

- Neoprene® Sponge

- Nitrile Sponge

- Silicone Foam

- Crosslinked Polyethylene Foam

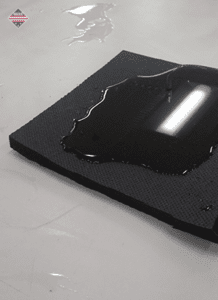

What does the Skin do on Sponge/Foam Materials?

The skin can provide a number of things, but typically the skins provide a greater degree of protection against encroachment such as unwanted intrusion of medias such as water. A solid rubber skin may be required for a greater degree of protection against abrasion. Some of the sponges listed above have a closed cell configuration, so even if a medium were to get past the initial surface, the integrity would be somewhat maintained. As discussed previously, this is a result of the ‘closed’ cells keeping the intruding media away. However, open cell sponges may entail something drastically different in this regard. A puncture to the skinned finish would prove detrimental to the integrity of the material on that respective side, as a result of the cells being open. When die-cutting & waterjet cutting parts, it is inevitable that one side of the sponge will be exposed. As ASTM D1056 notes: an open-celled material typically has a greater necessity for a solid rubber finish, while sometimes a skinned finish is not required for a closed-cell material.

What does the Finish of a Material Tell You?

One of the most amazing things about a skin finish on a material is that it tells you how it was manufactured. Each of the three materials below is manufactured differently, and the skin tells you how.

Typically the skins of sponges come in three formats:

- Smooth Skinned, as in Viton® Sponge which probably has some sort of smooth liner on both sides during the manufacturing process.

- Skived Finish, this is evident in Cellular Sponge Products such as Closed Cell Neoprene Sponge that is made from buns and then skived down.

- Fabric Finish, as in Silicone Sponge which has fabric on both sides as its going through the curing process.

More Information:

Another element that the fabric finish or smooth skin surface provides is an excellent contact surface for pressure-sensitive adhesives. If the PSA were to be adhered to the top of the cells it may prove difficult to gain a decent bond. The more surface area the PSA has to adhere to, typically the better the bond. With a smooth surface, the PSA has an opportunity to adhere consistently. For more information on sponge materials, or you have an application that you believe could utilize a sponge material, please contact sales@nedc.com.