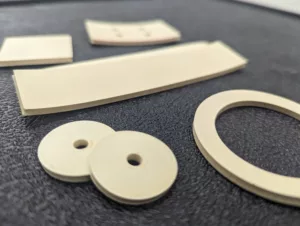

natural rubber gaskets/pads

It surprises me slightly, just slightly that we have posted over 220 blogs, but we have never discussed natural rubber. Natural rubber is called that because it was the first type of rubber discovered when the fateful Charles Goodyear accidentally dropped his natural rubber onto the stove with sulfur(sulfur is a curing agent, catalyst) in 1839. This vulcanized the rubber, and yureeka, natural rubber was created.

Where does Natural Rubber come from?

Natural Rubber come from the Hevea Brasilensis Tree in countries like Thailand, or Malaysia. Its drawn similar to a process like sap for Maple Syrup.

Information on Natural Rubber Products (Gum Rubber)

Natural Rubber (Gum) is a good water seal. It comes in a few durometers. Natural Rubber can be a good general purpose seal. During World War II, a serious shortage was encountered. This led to the rubber environment we have now, with a litany of different rubber products including SBR, and other synthetic rubbers.

Properties of Natural Rubber Gaskets/Pads

-Good vacuum sealing

-Good Abrasion Resistance

-Good Anti-Vibration Properties

-Good use for Sealing water

-Good low temperature compression set resistance

-Poor resistance to chemicals, ozone, or other strenuous environments.

-Typically compliant to the 21 CFR 177.2600

Applications for Natural Rubber

-Moderate temperature ranges such as -60°F to 220°F.

-Water Sealing

-Tires

-Airbags

-Flooring

-Erasers

Possible Designations for Natural Rubber (NR)

-ASTM D2000 BA

-ASTM D2000 AA

-FDA 21 CFR 177.2600

More Information on Natural Rubber Products

NEDC die-cuts, and waterjet cuts these materials into natural rubber gaskets, and pads. Natural Rubber either comes in black, or the natural tan, off yellow color(light tan). We can supply natural gum rubber in a number of thicknesses ranging from 1/64’’ to .500’’. In addition, we can supply adhesive backing to aid in assembly since we are a 3M converter. For more information on natural rubber, please contact sales@nedc.com.